Cold-Formed vs. Rigid-Frame Metal Buildings

What are the differences between cold-formed metal buildings and traditional rigid framed? Essentially, they are very similar with some minor differences, the main difference being the primary framing and bracing.

What are the differences between cold-formed metal buildings and traditional rigid framed? Essentially, they are very similar with some minor differences, the main difference being the primary framing and bracing.

The primary framing on cold-formed buildings are a cold formed rather than built up material in rigid frames and are put together using Cee channels versus traditional welded “I-beams”. The bracing also has additional strapping on cold-formed buildings.

Currently, steel shortages and transportation delays are creating challenges across the steel building industry. Yet, many metal building buyers are finding ways around these hurdles by opting for cold-formed steel buildings, as opposed to rigid-frame metal buildings. Cold formed building are more readily available and can often be shipped in weeks verses months. “Cold-formed” steel buildings are a rugged and affordable alternative to traditional rigid-frame construction.

Why have cold-formed steel buildings become so popular in recent years, and what are some of the benefits that come with investing in them?

Side By Side Comparison

Cold Formed |

Rigid Framed | |

Building Codes | Same | Same |

Primary Framing | Bolted Cee Channels Straight Columns Galvanized Lighter Gauge Cold Formed | Welded I-Beams Tapered Columns Red Iron Built Up |

Secondary Framing | Same | Same |

Framing Connections | Screws and Bolts | All Bolts |

Column Spacing | Frames Are Spaced Closer Due To Lighter Gauge | Wider Bay Spacing Allows For Larger Doors on Sidewalls |

Bracing | Strapping | Cable & Rod X Bracing |

Roof & Wall Sheeting | Same | Same |

Trims, Sealant, Closures | Same | Same |

Anchor Bolts | Included | Not Included |

Insulation Packages | Same | Same |

Doors & Windows | Same | Same |

Foundation Plans | Included | Not Included |

Exterior Look | Same | Same |

Interior Look | Smaller Framing Member Cleaner Lines Galvanized Framing | Larger Framing Red Iron Framing |

Delivery | Shorter Lead Times | Longer Lead Times |

Shorter Delivery Times

Pandemic-related steel shortages and transportation challenges mean today’s metal building buyers may need to wait six months or longer before their buildings arrive at their jobsites. Cold-formed steel buildings have much quicker delivery times and are also lighter, leading to shorter turn times and lower shipping costs.

Superior Galvanized Framing

Unlike red framed buildings, most cold-formed steel buildings feature galvanized framing. The galvanized framing looks like silver and improves aesthetics by making the building feel brighter and more open, it also resists rust, making it especially well-suited for areas prone to high humidity and moisture.

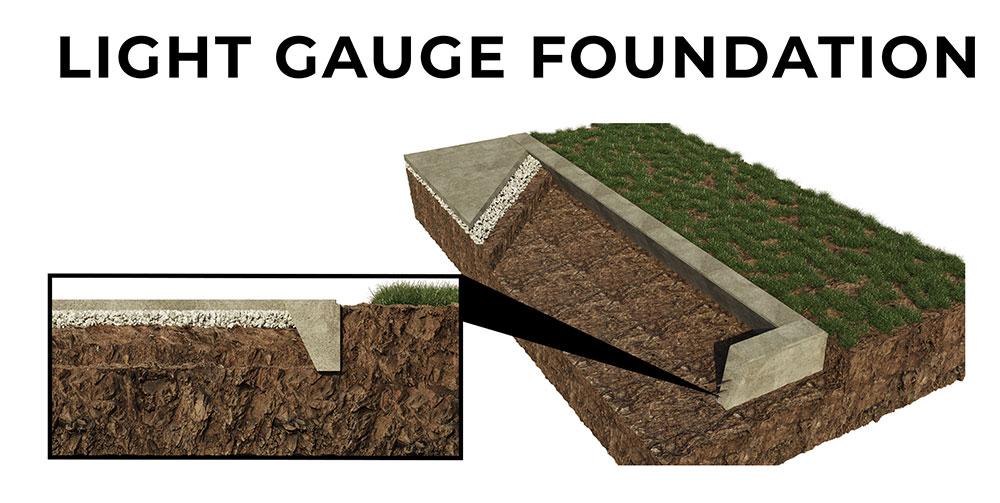

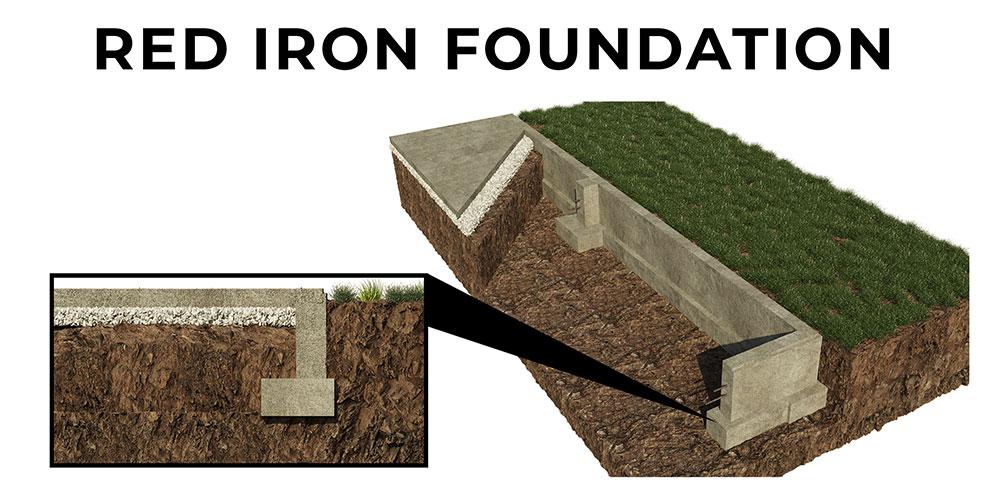

Lower Foundation Costs

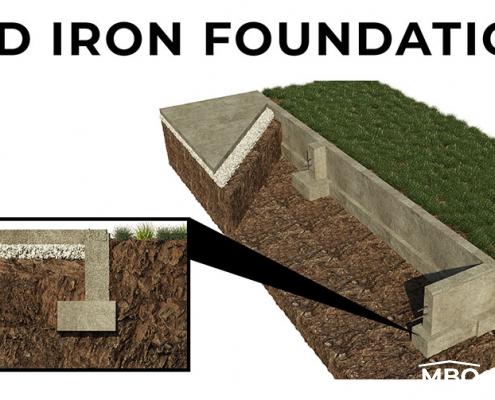

Cold-formed steel buildings are lighter than traditional red-oxide steel buildings and are typically designed with a single-pour thickened edge slab foundation and post-installed anchors. Even when cold-formed and red oxide steel buildings are the same size, cold-formed buildings do not require as much concrete for their foundations. Foundation costs for a rigid-frame steel building may eat up a large amount of a buyer’s budget, but foundations for cold-formed steel buildings use about 30% less concrete than alternatives, reducing foundation costs by as much as 25%.

Foundations for cold-formed steel buildings are also easier to construct than those needed for red oxide buildings because they require one pour, rather than two. Red oxide building foundations also require additional excavation and reinforcement of the footings, which comes at an additional expense. However, this is not the case with cold-formed buildings. Pouring foundation only once also helps reduce scheduling issues or conflicts and the amount of time your foundation contractor winds up spending onsite, resulting in additional savings.

Included Foundation Plans

Foundation plans also come standard with a cold-formed steel building, but this is not the case with a rigid-frame steel structure. This means cold-formed steel building buyers can skip the expense of hiring a foundation engineer.

Accessory Savings

Anchor bolts also come standard with cold-formed metal buildings, but not with rigid-frame buildings, saving you substantial money on accessories.

Design Flexibility

Cold-formed metal buildings have also come a long way in terms of design capabilities. When they first came onto the scene, most cold-formed steel buildings were relatively basic with minimal design options. Nowadays, cold-formed steel building buyers have many options for customizations. From architectural and aesthetic enhancements like standing-seam or gambrel roofs to mezzanines, monitors and lean-tos, cold-formed steel buildings have become easy to tailor to a buyer’s distinct needs and offer near-endless opportunities for customization.

Today’s cold-formed steel buildings are lighter, cheaper, and easier to work with than rigid-frame steel buildings, and they also help buyers avoid the delays and hardships associated with pandemic-era construction. Contact Metal Building Outlet to learn more about cold-formed steel construction and the many advantages that come with it.